Arge Robotik has been a well-known machinery manufacturer since 2007, specializing in small and medium caliber ammunition. The company is widely recognized as a reliable supplier of small caliber ammunition assembly lines in many countries. Recently, Arge Robotik has also expanded its production to include machinery for medium caliber ammunition manufacturing.

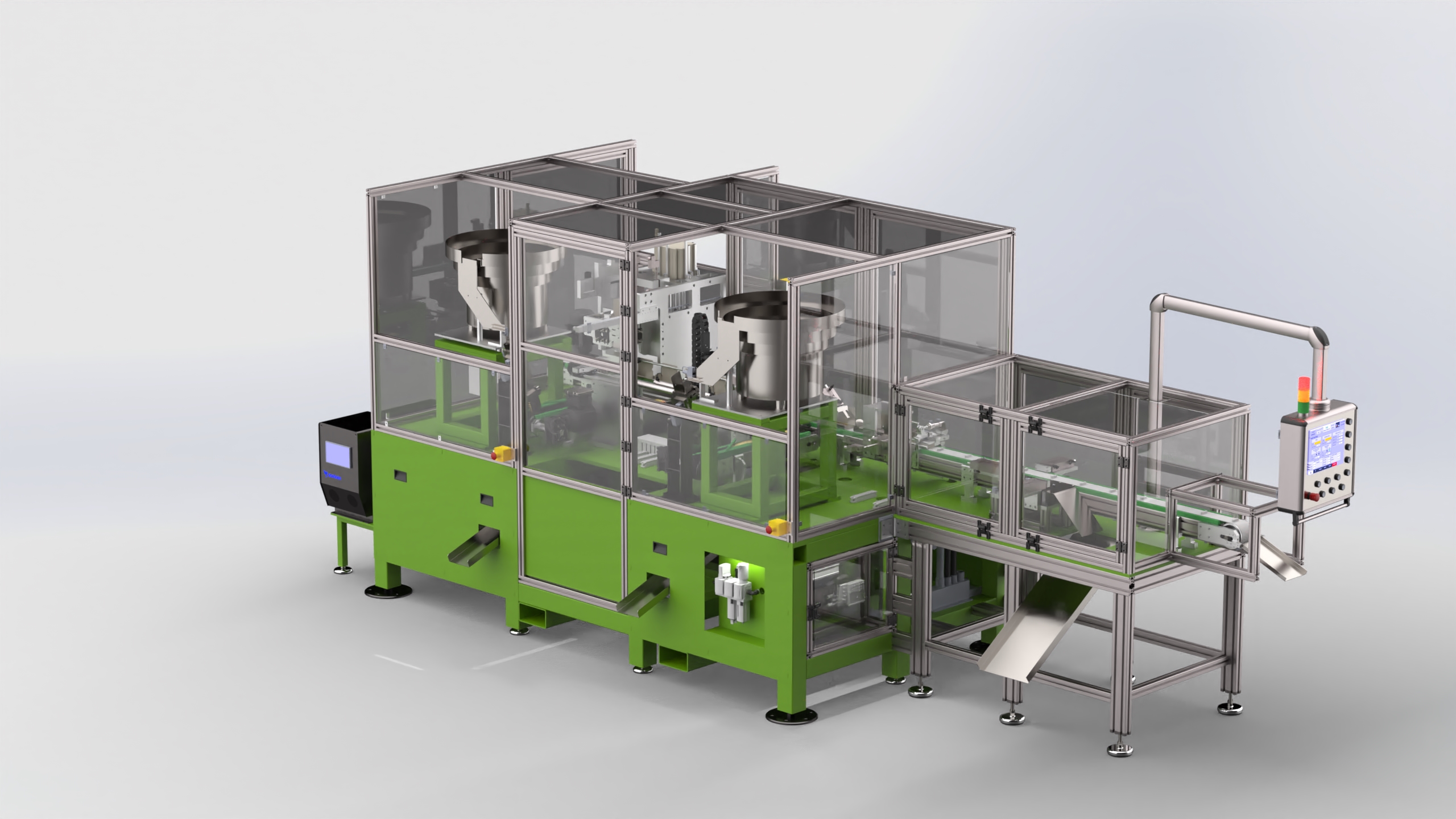

The fully automatic 5.56x45mm ammunition packaging machine developed by Arge Robotik is among the most reliable solutions of its kind worldwide. It is designed to efficiently pack 200 pieces of finished 5.56x45mm cartridges into carton boxes with high precision and consistency. What sets our machine apart is its integrated system that includes fully automatic carton erection using hot melt glue, along with multi-station quantity and weight verification. These features ensure accuracy, speed, and quality at every stage of the packaging process.

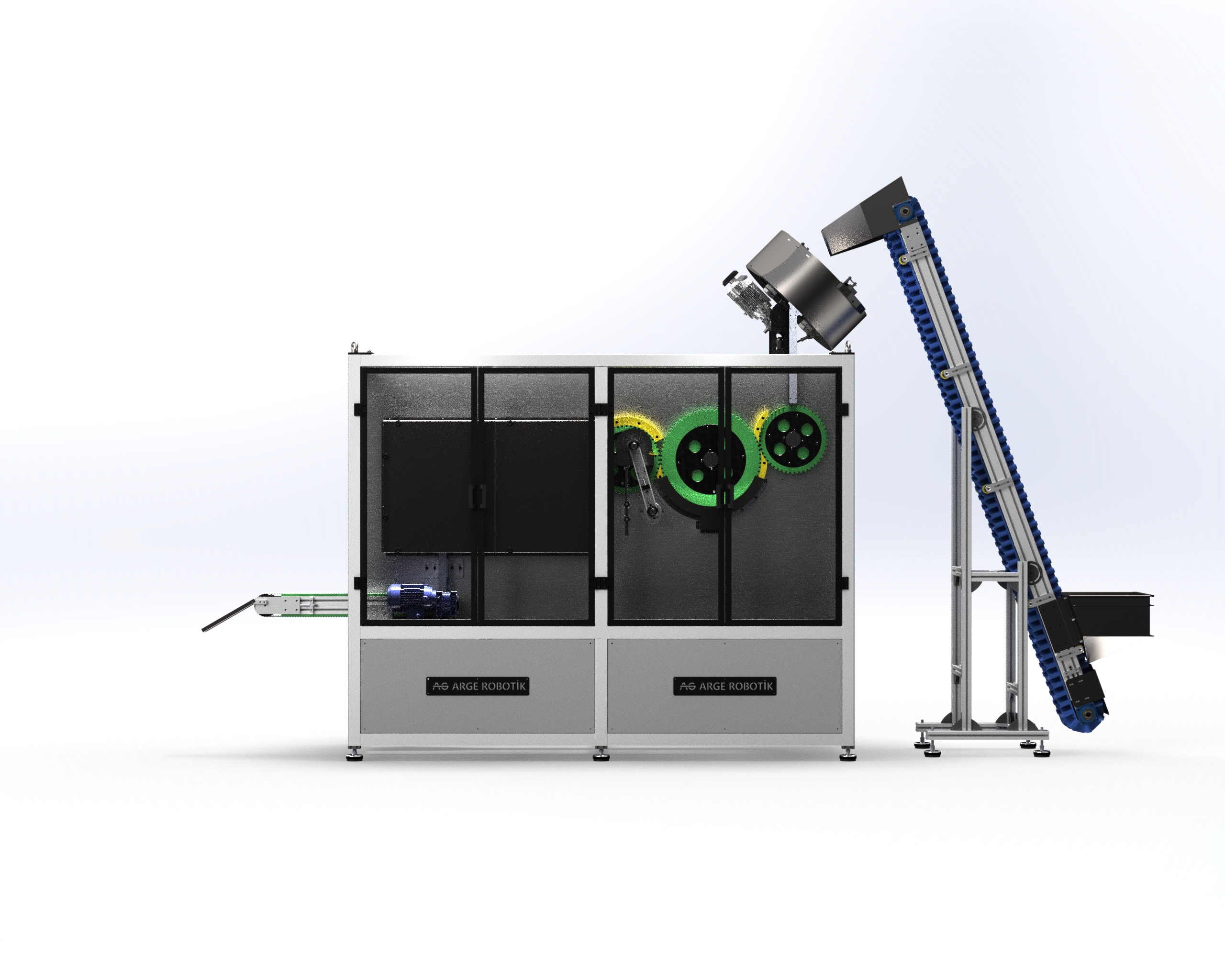

The primer pocket sealing and case mouth varnishing machine developed by Arge Robotik is among the most advanced solutions in the world for ensuring waterproofing and humidity protection in accordance with NATO standards. Recognized for its reliability and performance, this machine has been successfully delivered to and used in numerous ammunition factories worldwide.Based on Atex standards.

This fully automatic linking machine is designed to assemble 7.62×51 mm and 5.56×45 mm cartridges (both standard and tracer) into M13 and M27 links at a rate of 120 rounds per minute.

Arge Robotik's Trimming and Grooving Machine is designed for all small-caliber cartridge cases, providing precise length trimming and accurate groove formation in a single process.

This machine packs 9x19 pistol cartridges by stacking them in blocks of 50pcs. It places 50 bullets in the plastic separator. The operator makes a visual inspection in front of the machine. The bullets move forward by rotating on the conveyor. The operator manually separates the bullets with visual defects. Operators also put the bullets in cardboard packages. Our machine complies with Atex Zone2 requirements.

2000 ppm per shift.

3600pph.

120ppm.

120ppm.

250ppm.